03 "Matcha-Specific" Premium Black Granite - Cylindrical Shape with Polished Top and Bottom

This is a page for international customers.

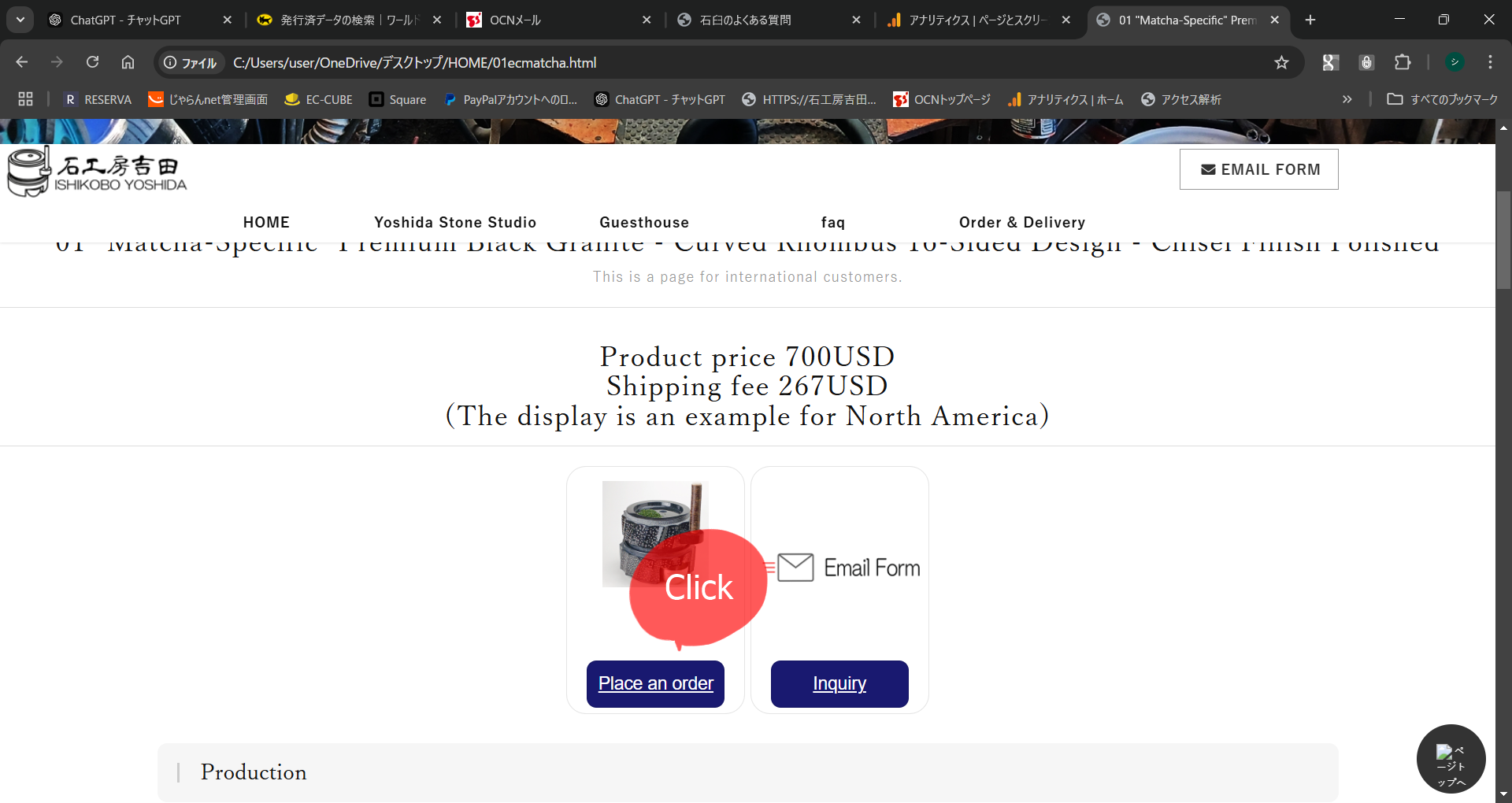

Product price 703USD €593

Updated on August 26, 2025

Production

The stone used is an exceptionally rare "premium black granite." This stone is characterized by its lack of crystalline grains and its higher specific gravity compared to other granites.

The design is a very simple cylindrical shape.

This traditional millstone form has been refined with modern processing techniques, requiring precise craftsmanship to achieve a perfectly accurate, distortion-free circular shape.

This is a stone mill specifically designed for grinding tencha into fine matcha powder.

With standard stone mills, grinding fine powder requires carefully feeding the tea leaves in small amounts. However, my matcha mill allows you to add the entire desired quantity of tea leaves, and simply continue turning the upper millstone to produce fine matcha powder effortlessly.

The upper millstone is designed to hold enough material for two servings (approximately 20g) at a time. However, it can be used repeatedly to grind larger quantities without generating heat, which could cause "burning" and affect the flavor.

(Excessive heat is known to increase bitterness in coffee and other materials.)

The grinding surface diameter was determined through prototypes to ensure sufficient grinding capacity without over-grinding and is set at 5.0 sun (approximately 15 cm). The height of the upper millstone was calculated based on the required weight.

The lower millstone features a donut-shaped groove around the outer edge of the 5.0 sun (15 cm) grinding surface. This groove is 8?9 bu wide (24?27 mm) and 5 bu deep (15 mm), designed to collect the ground powder.

The donut-shaped groove includes a single "hole," through which ground powder is swept by a "brush" attached to the underside of the upper millstone. With each rotation, the powder falls through the hole into the groove.

The "hole" in the lower millstone is crafted to accommodate a "tray," with dimensions of 10 cm width, 10 cm depth, and 6 cm height. This design determines the height of the lower millstone.

Product Details

| Shipping Cost | It depends on the country or region |

|---|---|

| Stone Material Used | Granite (Premium Black Granite) |

| Height | Approximately 21 cm (excluding when the handle bar is attached) |

| Weight | Upper Millstone = 10 kg Lower Millstone = 11 kg Total = 21.0 kg |

| Outer Diameter | Lower Millstone Diameter = 24.0 cm Upper Millstone Diameter = 21.0 cm Required Installation Diameter for Rotation with Handle Bar Attached = 32.0 cm or more |

| Handle | SAKURA (Natural Wood) |

| Timeframe from Order to Shipping from Japan |

2?3 days if in stock; approximately 10 days for new production. |

Detailed Design Specifications

The stone used is an exceptionally rare "premium black granite." This stone is characterized by its lack of crystalline grains and its higher specific gravity compared to other granites.

In general, matcha mills require users to add tea leaves gradually while grinding. However, if the amount added is not consistent, the particle size of the matcha can vary.

My matcha mill is specifically designed for grinding matcha only, ensuring that even those unfamiliar with using stone mills can produce uniformly ground matcha.

To use, simply add all the tea leaves (tencha) you wish to grind into the top hole of the mill. Then, continue turning the upper millstone.

The ground matcha is collected by an attached brush and directed into the container, making the process efficient and user-friendly.

The position of the hole relative to the center point also plays a role in grinding performance and efficiency. While it might seem that ground powder exits from all around the millstone's circumference, observation reveals that it only discharges from one specific spot on the upper millstone. Because this spot rotates, it creates the appearance of uniform discharge across the entire circumference. This specific spot on the upper millstone is located between 45 and 90 degrees counterclockwise from the handle attachment point. The reason for this range lies in the pressure distribution on the grinding surfaces. When the millstone is stationary, the pressure is evenly distributed. However, when the handle is attached and held with the right hand, additional force is applied to the handle attachment area, increasing pressure in that region. This increased pressure at one spot causes a decrease in pressure on the opposite side of the grinding surface. When the millstone rotates, the high-pressure area prevents the powder from entering, so the powder is pushed out slightly before reaching the high-pressure zone. The area where the coffee beans are first crushed often causes the upper millstone to lift slightly. To counteract this, the crushing force must be aligned with the line connecting the handle and the center point. Since the handle generates force not directly downward but angled toward the rotation direction, the hole must be located 90 degrees forward in the direction of rotation from the handle attachment. Both the size and position of the hole are determined based on careful observation, imagining the internal flow of the powder, and verification through prototypes and testing.

A common misconception is that the upper and lower grinding surfaces are entirely in contact. In reality, only a portion near the outer edge is in contact, with a gradually widening space extending inward toward the center. Materials fed into the millstone are crushed into smaller pieces step by step, eventually turning into powder at the outer edge and being discharged. This step-by-step grinding process is influenced by the structure of the "fukumi" (space), which is designed to narrow progressively to ensure materials are crushed into increasingly smaller particles. When grinding larger materials such as soybeans, the depth of the fukumi needs to be greater, ideally about half the diameter of the material. For smaller materials like sesame seeds, the depth of the fukumi is minimal or nearly nonexistent. Understanding the function of the fukumi and designing it with precise and adequate dimensions is crucial. If the fukumi is not properly designed, it can lead to issues such as large amounts of material remaining inside the millstone after grinding, or materials not entering the grinding space at all, causing them to simply spin around at the bottom of the "material feed hole" without being ground.

A brush, hidden beneath the handle of the upper millstone, collects the ground powder during rotation. The powder is automatically deposited into a container through a hole in the groove designed to catch it. When grinding coffee beans, a small amount of powder may scatter. To prevent this, the grinding surface is recessed below the outer edge of the powder groove. This requires precise machining, but it effectively minimizes powder scattering around the millstone. Note: For matcha millstones, there is no powder scattering, so the grinding surface does not require this recessed design.

Order & Delivery

Order

Even if the customs duty is 0%, VAT (Value Added Tax) may be applied upon import.

Standard VAT Rates in Major EU Countries (as of 2024):

Germany: 19%

France: 20%

Italy: 22%

Spain: 21%

Netherlands: 21%

VAT is calculated based on the CIF price (Product Price + Shipping Cost + Insurance Fee).

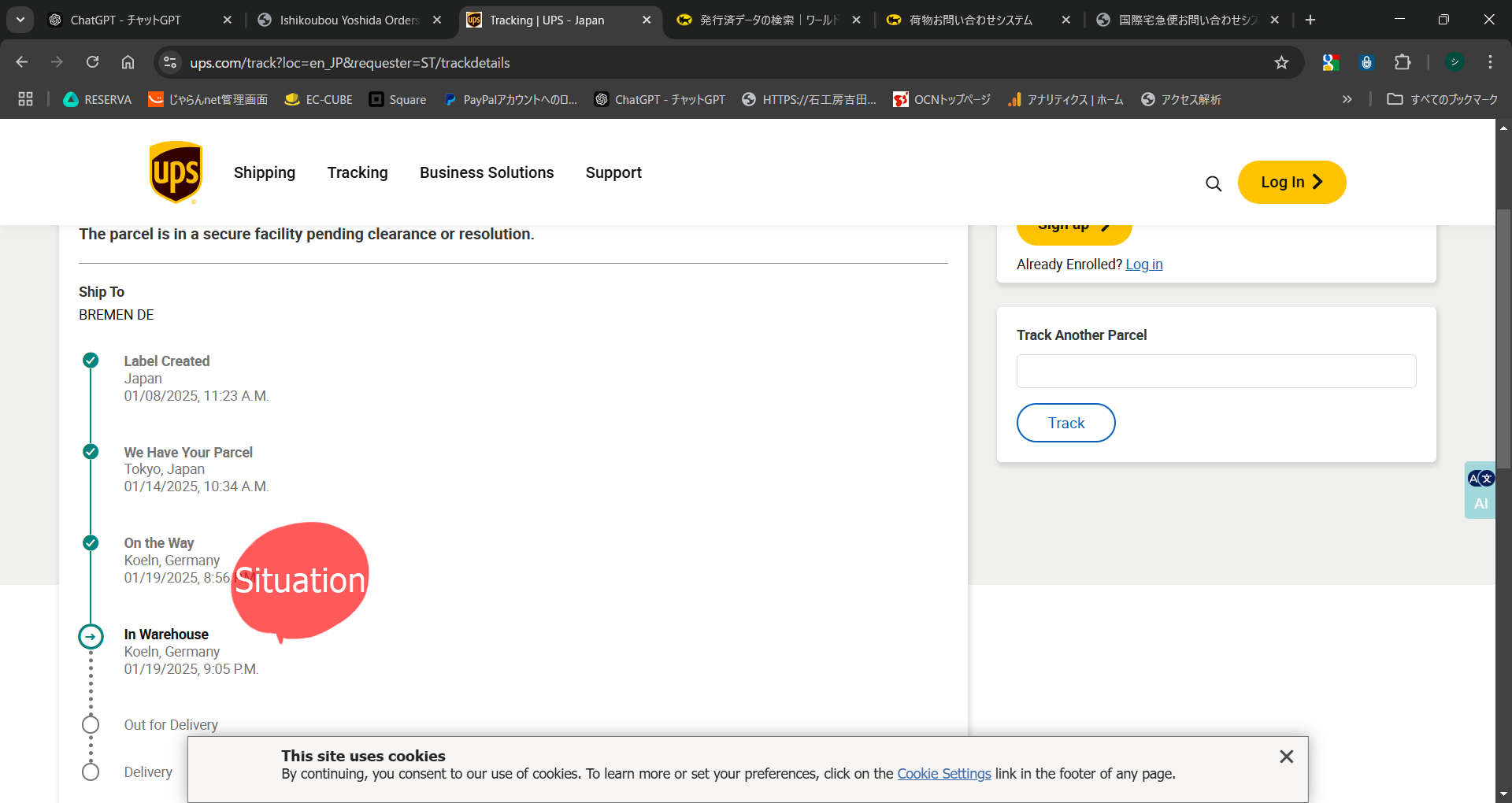

For orders to Germany, the customs authorities require the submission of an [order confirmation with shipping costs] and a [proof of payment]

Please note that taxes will be applied to the total amount, including shipping costs

Until the required documents are submitted, the shipment status will be displayed as [awaiting customs clearance] or [in transit]

Payment Methods

I will send the total amount for the product and shipping via [PayPal] to your email address. Please follow the instructions on the screen and enter your credit card information.

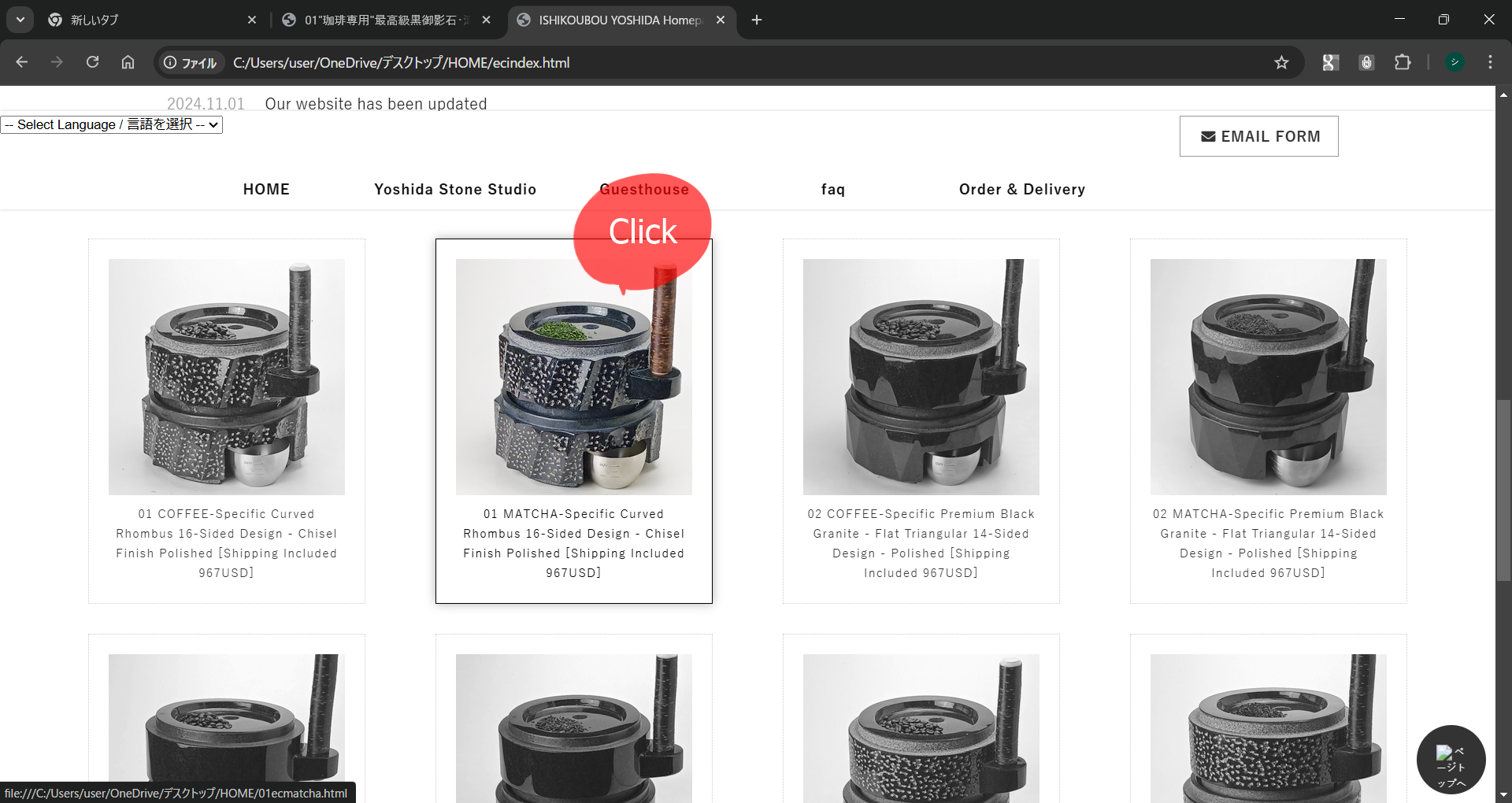

Home page

On the homepage, select a product and click on it.

Product selection

After moving to the product details page, click on [Place an order].

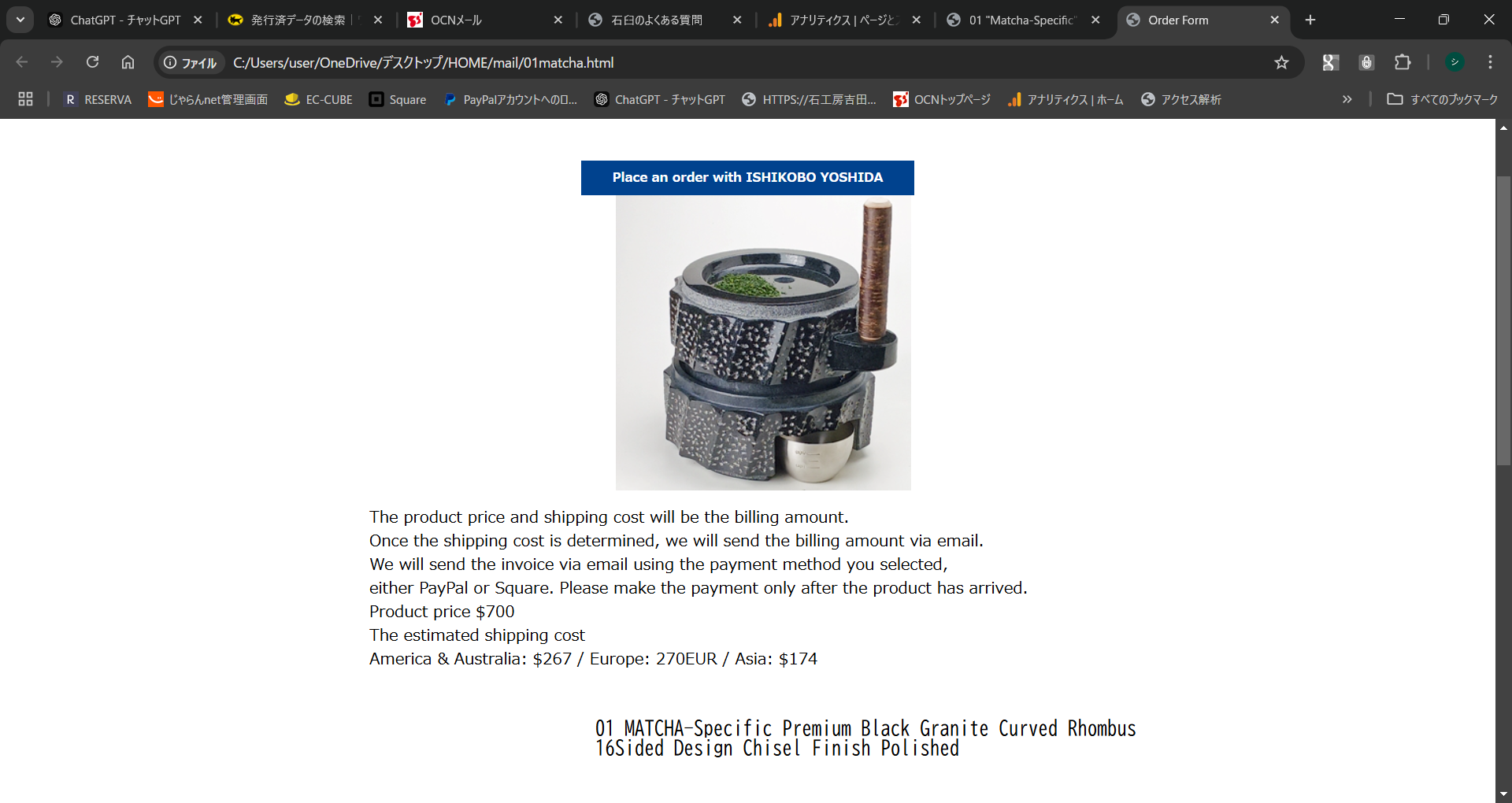

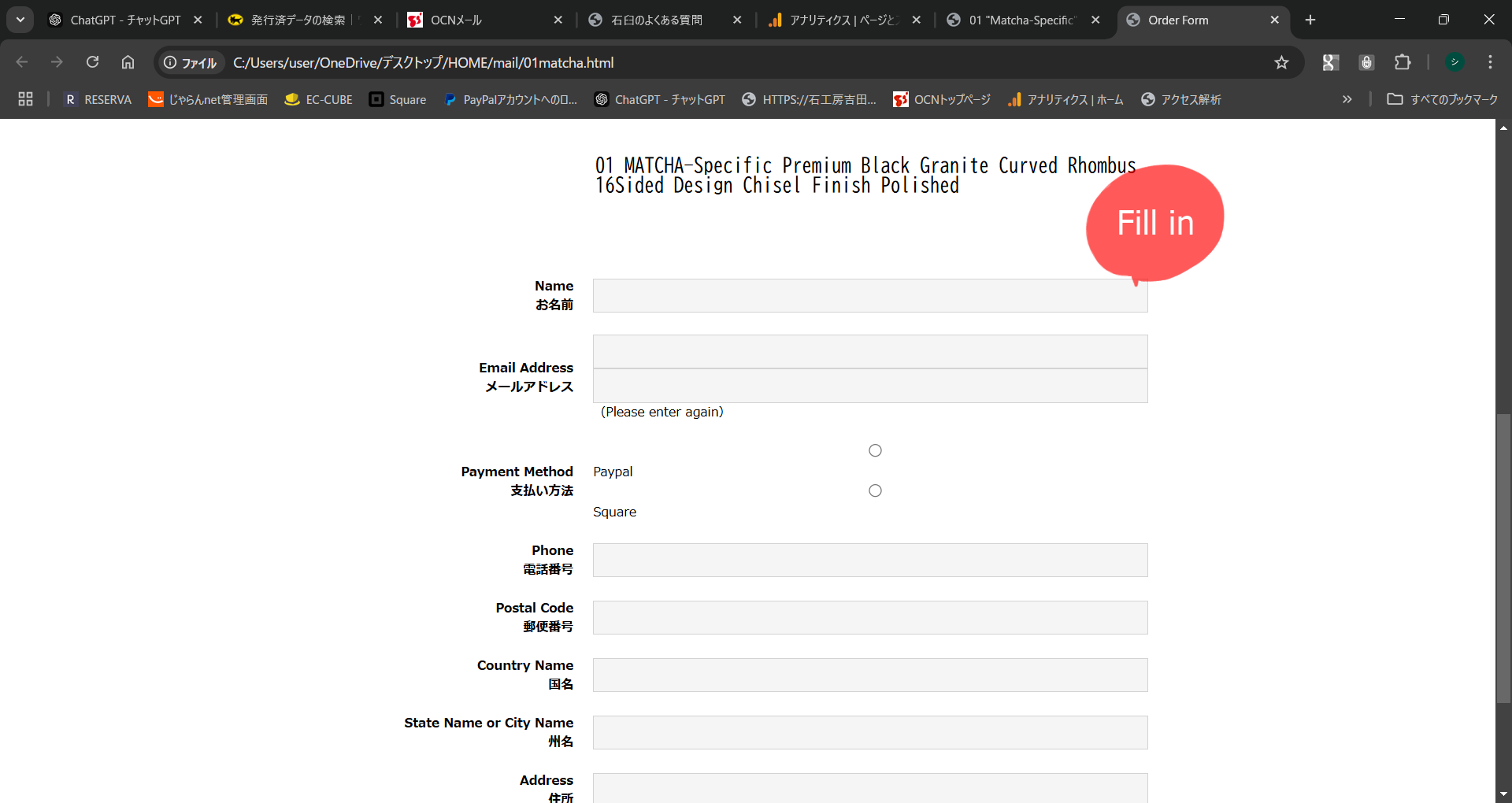

Order page

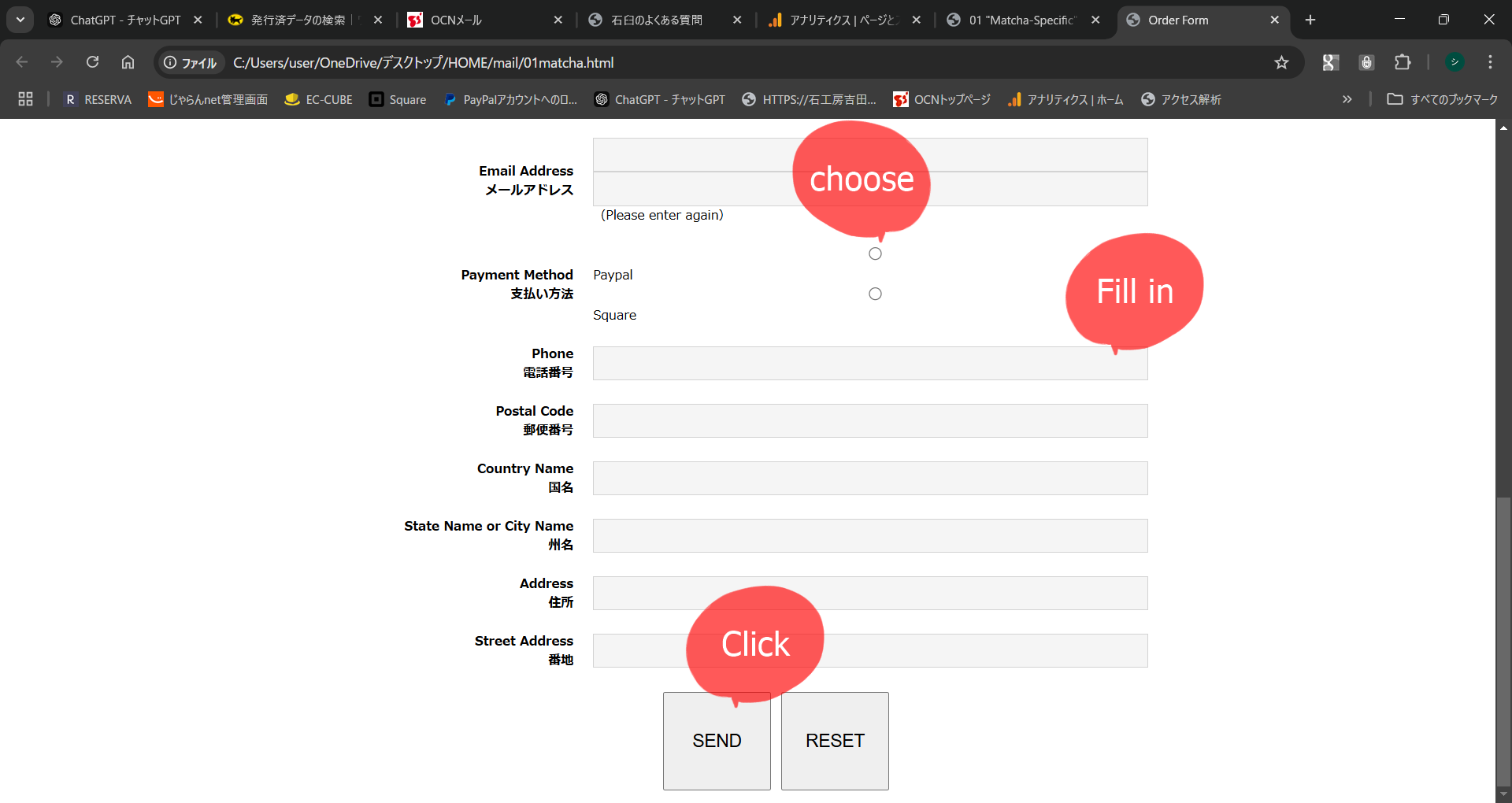

A separate window for placing the order will open.

Please confirm that the selected product is correct.

Enter information

Please enter your information.

If there are any mistakes in this information, the product may get lost, so please fill it out accurately.

Pay special attention to your email address, as it is important for communication.

Shipping Method Selection

Since the shipping cost and delivery time vary depending on the shipping method, please specify either one.

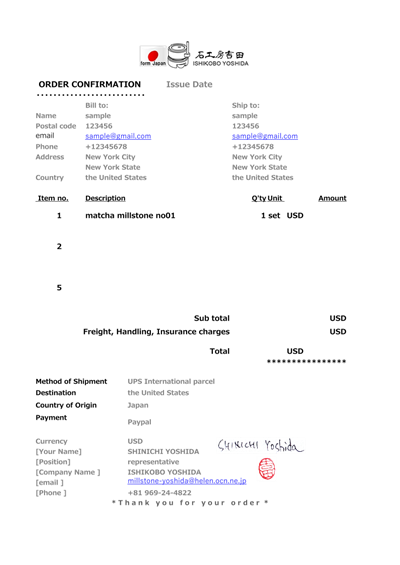

Order Confirmation Document

We are sending you an Order Confirmation to ensure there are no mistakes in your order details.

Please carefully check the contents, including the delivery address and total amount.

The email will be sent from millstone-yoshida@helen.ocn.ne with the subject line "ISHIKOUBOU YOSHIDA".

Please note that it may be mistakenly classified as junk or spam mail, so kindly check your spam folder as well.

Delivery

For air shipments, deliveries to North America, Australia, and New Zealand will be handled by UPS.

For other regions such as Europe and Asia, we use international parcels delivered by each region's local postal service.

For sea shipments, all regions will be handled as international parcels through the respective local postal services.

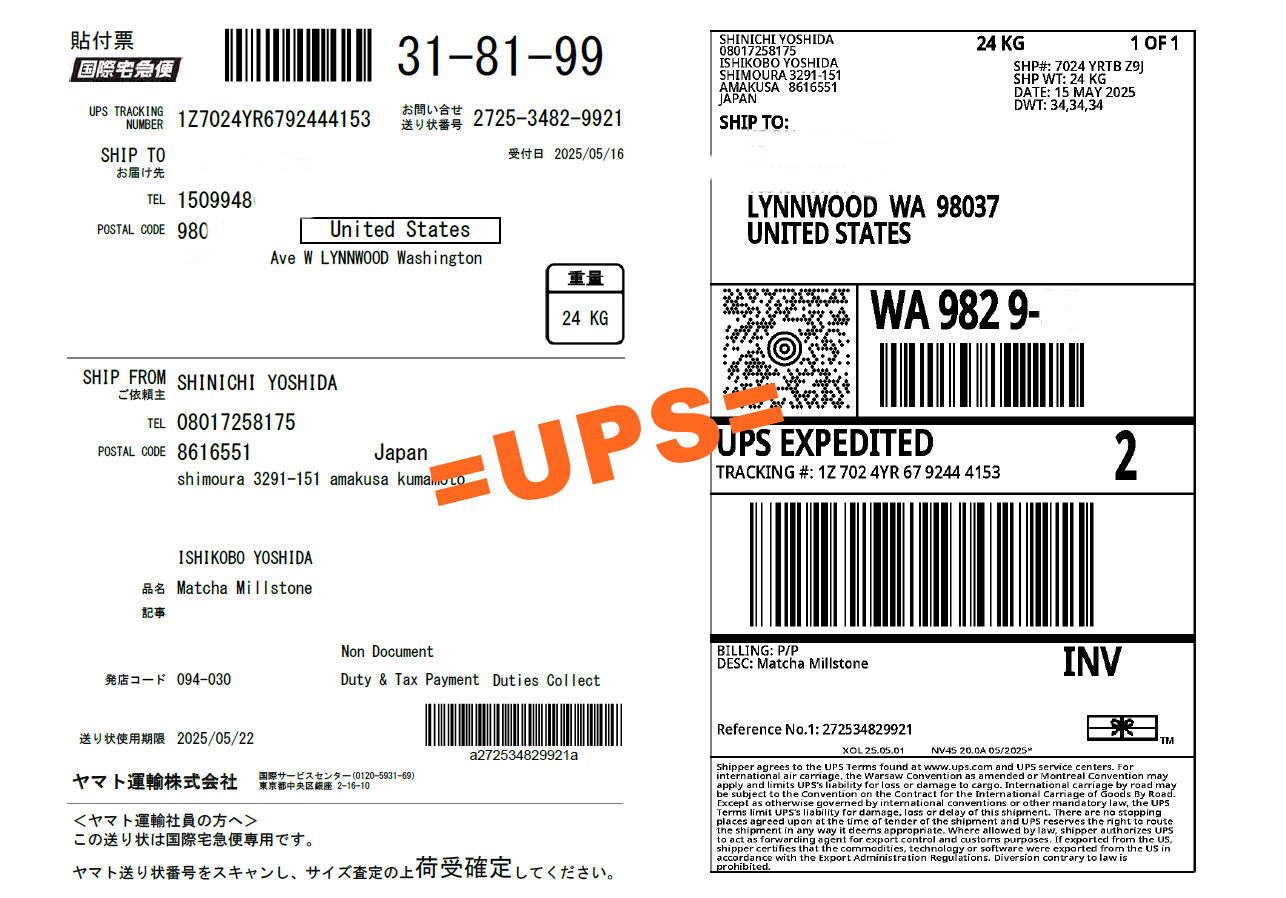

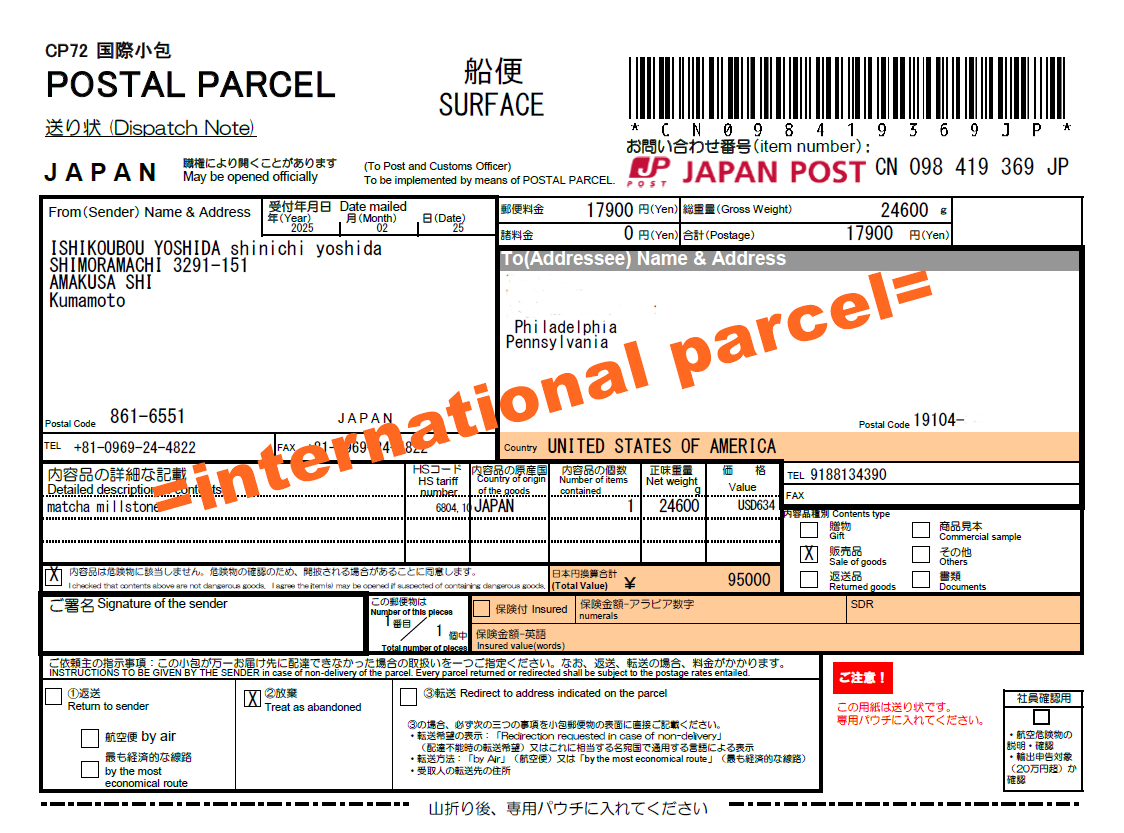

Product Shipment

Once the product is ready for shipment,

we will send you an email containing the shipping label PDF and the PayPal invoice.

Please check the shipping label carefully to ensure all details are correct.

Open the PayPal invoice notification and proceed with the payment.

The shipment will be made only after the payment is confirmed.

(We are unable to proceed with the shipment if payment has not been verified.)

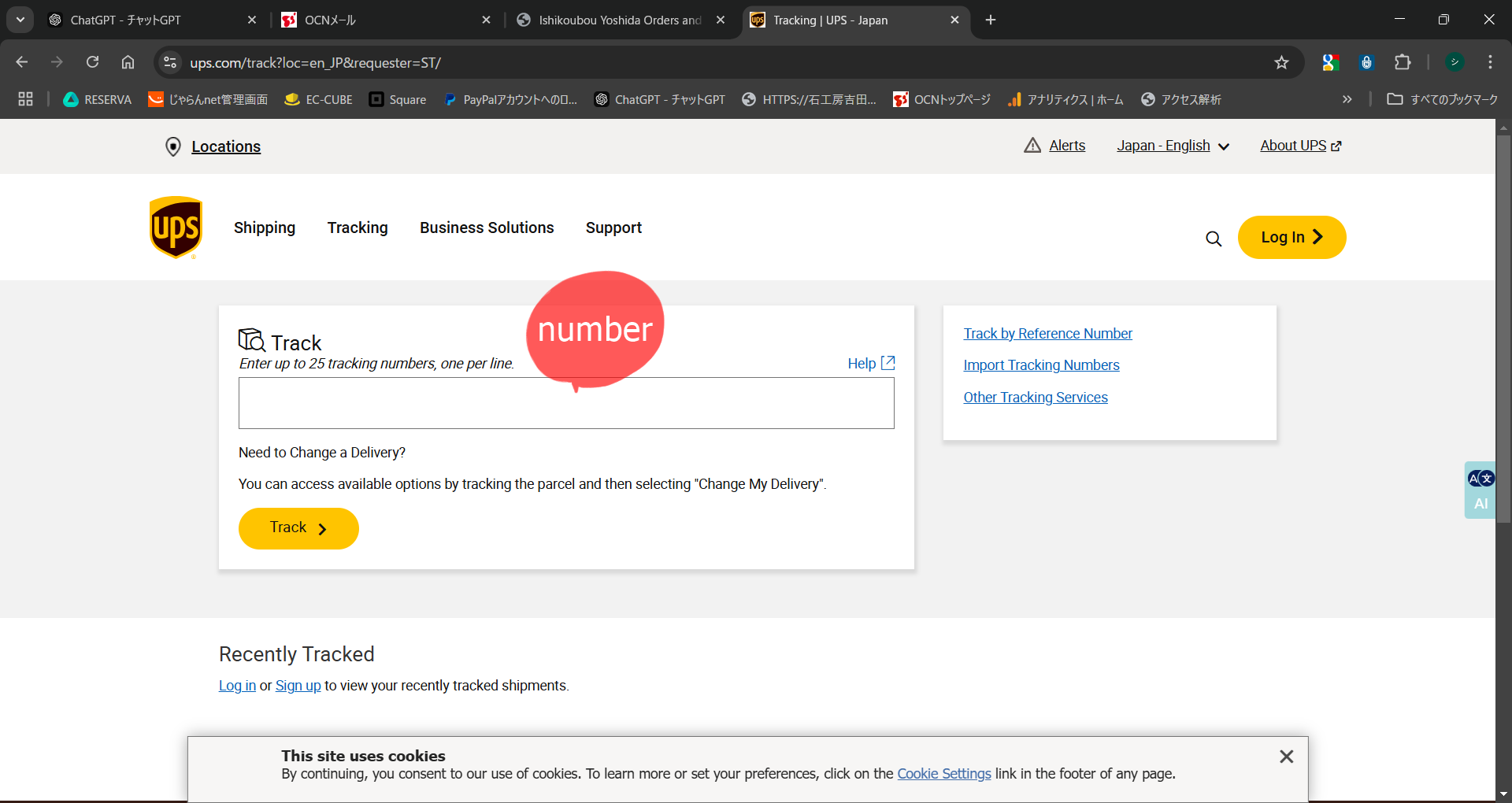

Tracking of the delivery

Once the product has been shipped, we will email you the tracking number.

Please access the UPS tracking page.

Current location of the product

The location of the product at the time of inquiry will be displayed.

Lost Product

UPS deliveries can sometimes be inaccurate and may result in the package being delivered to a hub in a different town from the specified address, causing delays.

In such cases, since our company in Japan cannot directly provide instructions to UPS,

we may ask the recipient to contact UPS directly for further instructions.