06 Matcha black granite exclusively matte finish without powder collection brush

This is a page for international customers.

Product price $740 €617

Stone, Time, and Tea.

The moment you take it in your hands, its weight begins to speak quietly.

Crafted from exceptionally rare, high-grade black granite.

With an extremely fine crystal structure and a density higher than ordinary granite,

it is a material of quiet distinction.

The surface is finished in a restrained, matte texture.

Stripped of ornament, the form allows the character of the stone itself to emerge.

The handle is made from natural cherry wood, adding a gentle warmth to the cool stone.

When quality is given top priority, the mill grinds approximately one gram per minute.

A pace chosen not for efficiency, but for aroma and the beauty of the particles.

The ground matcha falls quietly into the grooves of the lower millstone.

Intentionally, no brush for powder collection is included.

This allows you to observe the moment matcha is born from the stone.

Subtle steps are formed at the base of both the upper and lower millstones.

They allow the fingers to find a natural grip when lifting.

The central shaft is made of stainless steel and is resistant to wear.

The interior is equally durable, eliminating the need for re-sharpening.

Included is a stainless steel cup designed to reduce static electricity.

The completeness of this tool resides in such details.

Notes on Use

Matcha ground by the millstone collects in the grooves and,

by design, falls directly through an opening in the groove into the container below.

Please clean the interior after use.

This is a tool that becomes complete through time spent with its owner.

When grinding tencha, place the entire amount of tea leaves into the opening before beginning to turn the mill.

Although adjusted for tencha, gyokuro and similar teas can also be ground by adjusting the quantity used.

In rare cases, tea leaves may remain inside the opening.

If this occurs, gently push them through using chopsticks or a similar tool.

Product Details

Consumption tax: Tax-exempt product

Shipping: Covered by our company

Height: Approx. 21 cm (excluding handle rod)

Weight: Upper millstone 10.5 kg / Lower millstone 12.5 kg / Total 23.0 kg

Handle: Natural cherry wood

Delivery time: 2?3 days if in stock / Approx. 10 days for made-to-order production

Payment method: Online credit card payment (PayPal)

| International Shipping Fees | Air Mail | Sea Mail |

|---|---|---|

| Asia | $189 / Approx. 10 days /UPS/ International Mail | $93 / Approx. 25+ days / International Mail |

| USA | $260 / Approx. 10 days / UPS | $132 / Approx. 40+ days / International Mail |

| Europe | €291 / Approx. 10 days / UPS/International Mail | €85 / Approx. 50+ days / International Mail |

Production

The stone used in this product is the extremely rare "premium black granite."

This granite is unique because it has no crystalline particles and has a higher specific gravity compared to other types of granite.

The design is a very simple cylindrical shape.

To create a calm and refined atmosphere, the surface has been finished with a matte texture, reducing its gloss.

Precision shaping technology is required to achieve a perfectly symmetrical, distortion-free circular form.

This is a matcha-dedicated millstone specifically designed for grinding tencha into fine particles.

With a conventional millstone, you need to carefully grind small amounts of tea leaves at a time to achieve a fine powder.

However, with my matcha mill, you can simply add the desired amount of tea leaves and continue rotating the upper millstone, allowing you to effortlessly grind them into ultrafine matcha.

This product allows you to observe the matcha accumulating in the grooves as you grind.

The collected matcha can then be gathered using a brush and dropped into a container through a hole in the groove.

Detailed Design Specifications

My matcha mill is specially designed exclusively for grinding matcha, ensuring that even those unfamiliar with handling millstones can produce a consistent, high-quality powder.

How to Use:

Place the desired amount of tencha (tea leaves) into the upper hole.

Simply continue rotating the upper millstone.

The finely ground matcha will accumulate in the groove around the outer edge of the lower millstone.

Once grinding is complete, use a brush to gather the matcha and drop it into the prepared container.

Unlike other automatic powder-collecting millstones, this design prevents fine matcha particles from becoming airborne and allows you to enjoy the vivid green color of the freshly ground matcha as you grind.

The position of the hole relative to the center point also plays a role in grinding performance and efficiency. While it might seem that ground powder exits from all around the millstone's circumference, observation reveals that it only discharges from one specific spot on the upper millstone. Because this spot rotates, it creates the appearance of uniform discharge across the entire circumference. This specific spot on the upper millstone is located between 45 and 90 degrees counterclockwise from the handle attachment point. The reason for this range lies in the pressure distribution on the grinding surfaces. When the millstone is stationary, the pressure is evenly distributed. However, when the handle is attached and held with the right hand, additional force is applied to the handle attachment area, increasing pressure in that region. This increased pressure at one spot causes a decrease in pressure on the opposite side of the grinding surface. When the millstone rotates, the high-pressure area prevents the powder from entering, so the powder is pushed out slightly before reaching the high-pressure zone. The area where the coffee beans are first crushed often causes the upper millstone to lift slightly. To counteract this, the crushing force must be aligned with the line connecting the handle and the center point. Since the handle generates force not directly downward but angled toward the rotation direction, the hole must be located 90 degrees forward in the direction of rotation from the handle attachment. Both the size and position of the hole are determined based on careful observation, imagining the internal flow of the powder, and verification through prototypes and testing.

A common misconception is that the upper and lower grinding surfaces are entirely in contact. In reality, only a portion near the outer edge is in contact, with a gradually widening space extending inward toward the center. Materials fed into the millstone are crushed into smaller pieces step by step, eventually turning into powder at the outer edge and being discharged. This step-by-step grinding process is influenced by the structure of the "fukumi" (space), which is designed to narrow progressively to ensure materials are crushed into increasingly smaller particles. When grinding larger materials such as soybeans, the depth of the fukumi needs to be greater, ideally about half the diameter of the material. For smaller materials like sesame seeds, the depth of the fukumi is minimal or nearly nonexistent. Understanding the function of the fukumi and designing it with precise and adequate dimensions is crucial. If the fukumi is not properly designed, it can lead to issues such as large amounts of material remaining inside the millstone after grinding, or materials not entering the grinding space at all, causing them to simply spin around at the bottom of the "material feed hole" without being ground.

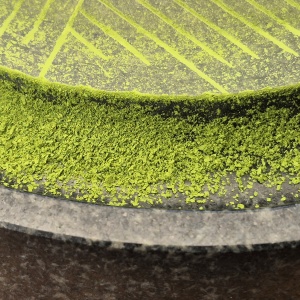

This is a photo of the lower millstone with the upper millstone removed during the grinding process.

As you can see, very few tea leaves remain inside the millstone.

To minimize waste of the precious TENCHA, the grinding surface of the upper millstone has been specially designed with a unique structure.

After grinding is complete, please use a stiff brush to clean any remaining powder from the fine grooves.